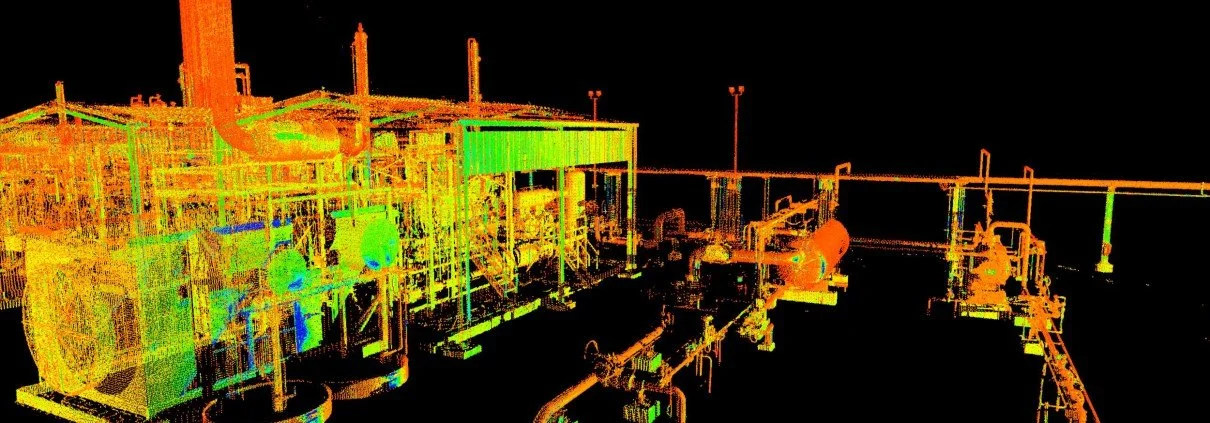

Impacting the Oil and Gas Industry: How LiDAR Technology is Reshaping the Sector

In the dynamic realm of the oil and gas industry, innovation is a driving force that continually shapes operations, efficiency, and safety. Among the transformative technologies taking center stage, LiDAR (Light Detection and Ranging) has emerged as a pivotal tool, revolutionizing the way oil and gas companies explore, extract, and manage resources.

Decoding LiDAR in the Oil and Gas Industry:

LiDAR technology, powered by laser pulses, creates detailed 3D models of objects and landscapes by measuring the time taken for laser beams to travel to and from surfaces. This data, in the form of point clouds, is a valuable asset in understanding and managing complex oil and gas environments.

Applications in Oil and Gas:

Exploration and Reservoir Characterization: In exploration, LiDAR aids in understanding subsurface geology and reservoir characteristics. It provides accurate elevation data, allowing geologists and engineers to better comprehend potential drilling locations and reservoir structures.

Pipeline and Facility Design: LiDAR-generated topographical maps help design pipeline routes and facility layouts. Precise terrain data assists engineers in planning optimal pathways, avoiding obstacles, and minimizing environmental impact during construction.

Infrastructure Integrity and Monitoring: The oil and gas industry's vast infrastructure requires meticulous monitoring. LiDAR scans offer detailed assessments of pipelines, wellheads, and other equipment, enabling early detection of corrosion, leaks, or structural issues.

Safety and Emergency Response: LiDAR-equipped drones can swiftly assess remote or hazardous sites, assisting emergency response teams in assessing the severity of incidents and determining the best course of action, thus enhancing worker safety.

Environmental Compliance: Oil and gas operations often coexist with sensitive ecosystems. LiDAR provides precise data for environmental impact assessments, aiding in compliance with regulations and minimizing ecological disturbances.

Boosting Efficiency and Precision:

Integrating LiDAR technology into oil and gas operations has transformative implications. The technology accelerates surveying and data collection, providing real-time, high-resolution information for decision-making. As a result, operational efficiency is enhanced, project timelines are shortened, and resources are optimized.

The accuracy of LiDAR data is paramount in an industry where even the smallest deviations can lead to significant consequences. By generating detailed, precise representations of complex environments, LiDAR helps engineers and operators make informed choices, leading to safer and more productive operations.

LiDAR technology's integration into the oil and gas industry has opened doors to improved efficiency, safety, and sustainability. Its capacity to provide highly accurate, real-time data is revolutionizing exploration, production, and environmental management. As the industry evolves in response to technological advancements, LiDAR stands as a beacon of progress, fundamentally reshaping the way oil and gas resources are discovered, extracted, and maintained.