How LiDAR Technology is Shaping the Future of the mining Industry

The mining industry, known for its demanding operational challenges and high-stakes endeavors, is undergoing a transformative revolution thanks to advancements in technology. Among the most impactful innovations, LiDAR (Light Detection and Ranging) technology has emerged as a game-changer, revolutionizing the way mining operations are planned, executed, and managed.

Understanding LiDAR Technology in Mining:

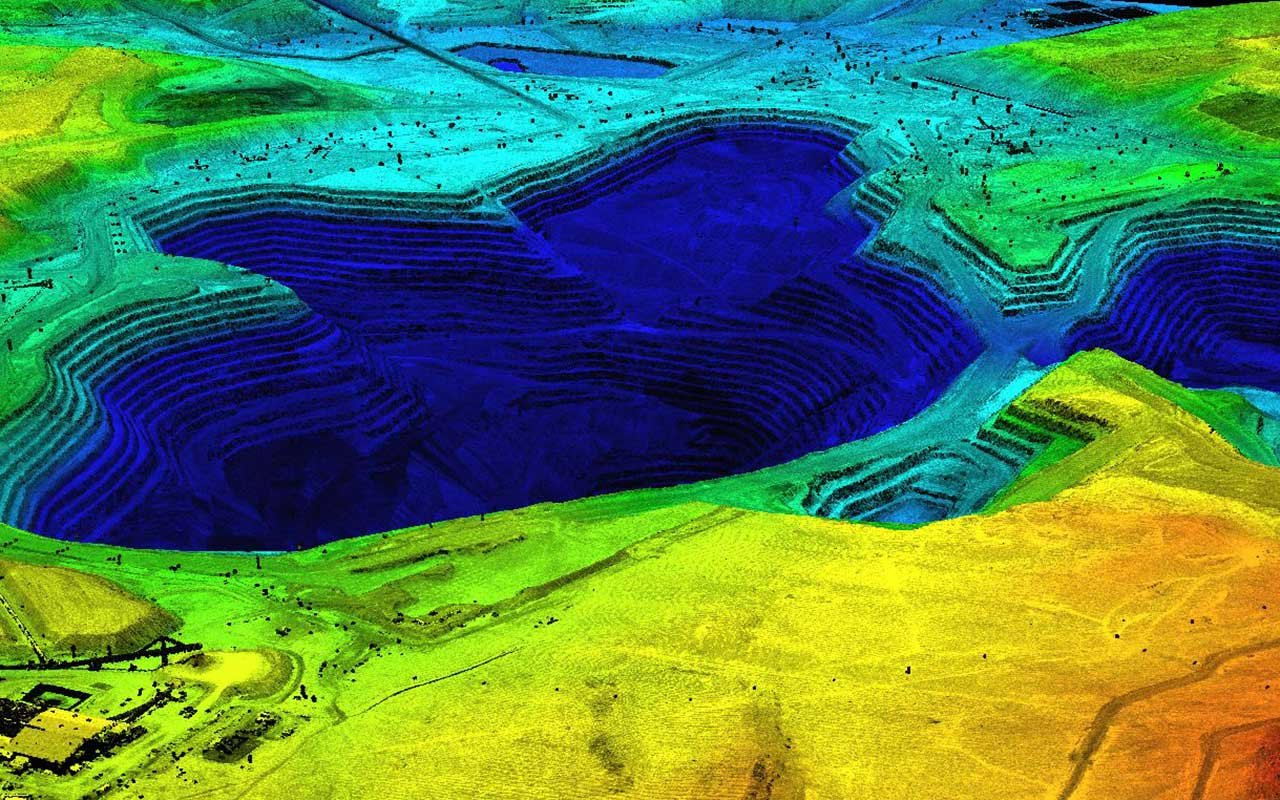

LiDAR technology, based on laser scanning principles, enables the creation of highly detailed and accurate 3D representations of objects, surfaces, and landscapes. By emitting laser pulses and measuring their travel time to and from objects, LiDAR systems generate "point clouds" of data that accurately depict the physical environment, making it a crucial tool in the mining sector.

Applications in Mining:

Exploration and Resource Assessment: LiDAR technology plays a pivotal role in geological surveys and resource assessment. By scanning large areas of terrain, LiDAR generates detailed elevation models, aiding geologists and mining engineers in identifying potential ore bodies, evaluating deposits, and planning exploration activities.

Terrain Analysis and Planning: Mining operations often take place in rugged terrains with challenging landscapes. LiDAR scans provide precise topographical data, helping mining companies plan infrastructure, access routes, and extraction strategies while minimizing environmental impact.

Stockpile Monitoring and Volume Calculations: LiDAR-equipped drones or vehicles can quickly capture data on stockpiles of minerals or ores. This data is then used to calculate stockpile volumes accurately, aiding in inventory management and resource optimization.

Safety and Risk Mitigation: Mining environments are inherently hazardous, with safety being a top priority. LiDAR scans help monitor pit slopes, tunnels, and highwalls for potential stability issues, contributing to early detection of safety risks and enhanced worker protection.

Reclamation and Environmental Management: After mining operations conclude, site reclamation becomes crucial. LiDAR scans assist in monitoring the progress of reclamation efforts, ensuring compliance with environmental regulations and minimizing the ecological impact of mining activities.

Increasing Efficiency and Precision:

LiDAR's integration into mining operations has revolutionized efficiency and accuracy across various aspects of the industry. From exploration and resource estimation to operational planning and safety management, the technology provides comprehensive, real-time data that enables smarter decision-making and optimized processes.

By rapidly capturing detailed terrain information, LiDAR reduces the time and resources required for traditional survey methods, improving project timelines and reducing costs. Additionally, the precision of LiDAR data minimizes errors and uncertainties in resource estimation and extraction planning, leading to more productive and sustainable mining practices.

LiDAR technology's integration into the mining industry has unleashed a new era of efficiency, safety, and sustainability. Its capacity to provide highly accurate, real-time data is revolutionizing every stage of mining operations, from exploration and planning to production and reclamation. As mining companies increasingly harness LiDAR's capabilities, the industry is poised for higher efficiency, reduced environmental impact, and elevated safety standards. In an era of technological transformation, LiDAR stands as a beacon of progress, fundamentally altering the way we extract and manage Earth's resources.